Corrkil

CORROSION CONTROL SOLUTIONS

ECO FRIENDLY ANTI CORROSION PRODUCTS

CORRKIL

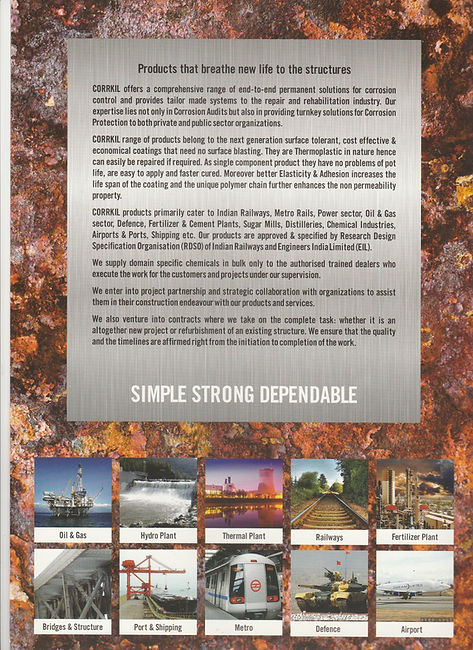

Ours is a company run by a team of well experienced professionals, retired senior government and public sector officials. We specialize in Corrosion Audits and providing Solutions for Corrosion protection to both private and public sector organizations. Our strength lies in extensive knowledge of products & systems which helps in undertaking Research & Development in newer areas and in providing consultancy and turnkey solutions to different types of anti corrosive problems. Besides this we also manufacture and source anticorrosive products as per the requirement of our clients.

The very fact that country is losing Rs 4 lakh crore per annum due to corrosion which is approximately 4-5% of GDP and is, of course, a huge amount, proves the seriousness of the problem. We understand that you people are also facing corrosion problem in a big way in your outdoor structures. Due to the unique nature of your problems you need some very specialized coatings solutions with long life.

Because of our deep understanding of the Corrosion mechanism we are able to provide our customers the most suitable solution available. We deal with most of the sectors like Oil & Gas, Hydro & Thermal power Plants, Railways, Fertiliser plants, Bridges & Structures, Ports & Shipping, Defense, Metro, Airports etc. and we have worked a lot in the corrosion problems of Indian Railways. Few years back, with rigorous R&D, we were able to develop specialized Co- polymeric Anti Corrosion Coatings (CORRKIL Range) and in due course Research Development Specification Organization (RDSO) of Indian Railways, after thorough testing and trials recommended our product to the Railway Board for the applications on Rail Tracks, OHE Fittings and Masts and Bridges and Structures. Since then we have been working closely with them.

We are presently working with RDSO on sixteen different applications in the areas like B&S, Tracks, Wagons, Passenger coaches, Civil Structures, Power Generation and Sewage etc. The RDSO Specification no PCN/M&C/121/2011(Copy attached) is prepared for our CORRKIL range of products. While working on these applications we realized that the problems were of diverse nature needing different specialized materials. Very soon we are also going to launch new next generation coatings like Plasma coatings, Water base coatings, Ceramic coatings and few more surface tolerant and Zero VOC coatings both in Thermoset and Thermoplastics.

Recently there were some unfortunate accidents due to the cracks & fractures in rail tracks. These cracks & fractures were formed due to certain factors and the main factors were due to Corrosion and Temperature variations. Due to this Indian Railways has decided to coat the tracks with the coatings which can provide good resistance to corrosion and insulation properties which can take care of temperature variations. Our coatings were specified by the RDSO for this particular application wide the above mentioned specification number PCN/M&C/121/2011. They are even considering to precoat the rails at their Flash-Butt welding plants with our products. As the Security and Safety of the passengers are the main concerns for you also we feel that the same type of treatment is required by you also. Our product was used in your airport line successfully (copy of order enclosed). Our product was used in many places in Indian Railways and Konkan Railways (copy of some tenders & orders are attached). We are also enclosing herewith the letter of 2008 by Indian Railways recommending our material for the Track Coatings and also enclosed is a copy of Satisfactory Performance report from SWR, Hubli.

Our Product is the next generation coating which is Thermoplastic in nature and also surface tolerant hence need no blasting of surface and only minimal manual surface preparation is required. It can also be easily repaired. Another major advantage is that when a recoat is needed then you just have to coat with one coat of the top coat and the old surface automatically becomes the primer.

Application on Bridges

We will like bring to your notice the work we have done in the field of Bridges & Structures as we feel that you people have the similar types of problems.

In 2013, the committee for coating systems for long painting-free life (15 years and above) for steel girder bridges on Indian Railways recommended field trials with three painting systems including our system(copy attached). Extracts from the report are attached for reference. This system was applied on the Kamanwadi Bridge in CR in 2015. Inspections were carried out by RDSO in 2016 and 2017, and the condition was found to be very good. Copies of the Inspection reports and the awarded tender are attached. A copy of the awarded tender for SR is also attached for reference.

Approval by EIL

EIL had also approved our products for application on off shore platforms of ONGC. Extracts from the specification for maintenance painting of well platforms LEWP ONGC is attached for reference. Copy of the approval certificate issued by EIL is also attached.

Approval by Indian Road Congress

Last our products were also approved by the Indian Road Congress (IRC) for the protection of their outdoor structures through our products.

Usage in Hydro power plants

Corrkil Range has been used by NHPC Ltd for the painting of Penstocks in their Hydro power plant in Manipur. Copies of tenders and orders issued by them are attached for reference

Advantages

Major advantages of using Thermoplastic Copolymeric Coatings Corrkil Range are as below:

-

Surface preparation is very easy. It does not require sand blasting. Simple hand tools can prepare surface. Since you structures and sites are such that blasting becomes a tedious and costly affair and despite all the hard work on such structures and sites. It is very hard to achieve the desired results of surface preparation and because of that you need to use our products where either no surface preparation or minimal preparation is required as our coatings are Surface Tolerant Coatings.

-

Single pack, ready to use hence easier to use at sites reducing wastage.

-

Excellent bonding. This is a very important property of a good Surface Lamination. As most of the structures are of metals which have a property of expansion- contraction and most of the coatings lose their adhesion and cracks because of lack of elasticity and hence fail. Our products are very elastic and match the coefficient of expansion-contraction of the metal taking care of this problem.

-

Excellent solvation property; repairs to the film can be carried out very easily. Hence maintenance is very easy.

-

Can be reapplied on old coatings.

-

Our coatings are not Sacrificial in nature like Zinc Rich coatings hence permanent in nature. They have very long life. We are enclosing herewith the report prepared by Indian Railways where our products are mentioned in the category of long life (15 years plus)

As you can notice that our products are used and specified by many prestigious clients regularly in highly corrosive areas. We feel that due to our approvals by prestigious Government Approval Agencies you will also be able to use our products regularly.

COMPARITIVE STUDY

CORRKIL SOLUTIONS

MANUFACTURING AND R & D

Photo Gallery 1 - Factory

Photo Gallery 2 - Factory Lab

Photo Gallery 3 - Factory Production

Photo Gallery 4 - Central Railway

PRESENTATIONS

Rail Surface Presentation

HPCL Gallery

Loktak Penstocks Gallery

DMRC Track Presentation

Pipe Coating Gallery

Nathpa Jhakri Gallery

Get in Touch

Office: 22, Naval Apartments,

Vasundhara Enclave, New Delhi - 110096

Factory: C149, Phase II Extn, Noida

corrkil@yahoo.com / Tel. 011-22627295, 43518295